Pros and Cons Together: User Report on Kubota KX161 Excavator

The Kubota KX161 is a flagship 6-ton class excavator from Kubota Japan, widely used in China. This model is fully imported, powered by a 47-horsepower engine, weighs about 5.7 tons, and comes with a 0.22 m³ bucket as standard. It also features a breaker pipe, a dozer blade, and an anti-theft key (note: after 2008, the STD version no longer includes the breaker pipe). Thanks to Kubota’s strong brand reputation, the KX161 has performed well in China’s market. So how does it really perform in daily use? Here is a genuine report from a user who owns two KX161s:

Purchase Date: March 2007

Total Hours: About 5000 hours so far

Purchase Cost:

- Down payment: 200,000 RMB

- Lease financing: 200,000 RMB

- Freight (Shanghai to Changsha): 5000 RMB

- GPS installation: 5000 RMB

- Total: 410,000 RMB

Warranty: 2000 hours or one year, whichever comes first; excludes fuel pump and injectors.

This was our family’s second Kubota excavator. Back then, in my hometown’s mountainous areas, road building, land clearing, and foundation digging created high demand for compact, maneuverable excavators with strong digging force and high mobility — you could easily clock 2500 hours a year.

Kubota’s local dealer at the time did a great job — the demo unit and the operator really built our confidence, and the dealer’s manager personally supported customers and expanded the local market. Without his team’s efforts, Kubota wouldn’t have achieved such a strong presence in Hunan.

About the GPS fee (5000 RMB):

This turned out to be quite disappointing. In the first year, I didn’t receive any useful GPS data like location, working hours, or fuel consumption. It was far behind the Komatsu KOMTRAX system. From the second year, the GPS service provider even tried to charge an extra annual fee of over 1000 RMB. I refused. Eventually, they removed the GPS, claiming it was damaged by water — I suspect they just reused it on another machine. Very frustrating.

Compared to local brands:

Domestic mini excavators like SANY, Liugong, and Yuchai often use premium imported components (Isuzu, Yanmar, Cummins engines; Rexroth, KYB hydraulics). However, I feel the real difference lies in design philosophy, assembly quality, and electronic control details.

Electronic control:

- Electronic throttle (auto-idle)

- Auto preheat on startup

Monitor displays:

- Engine hours, RPM, coolant temperature, oil pressure, fuel level, battery voltage, overheat protection, alternator warning.

Switches (left to right):

- Switch 1: Headlights

- Switch 2: Breaker mode

- Switch 3: Short press/long press for different screens

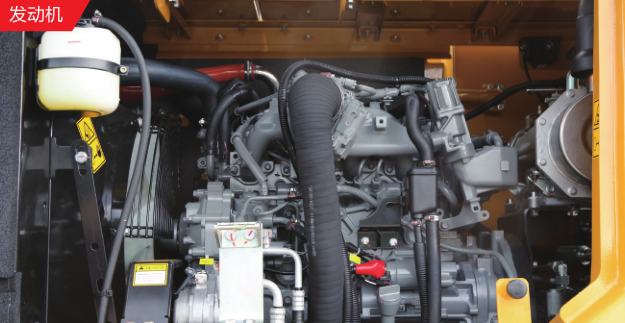

Engine:

The Kubota engine runs surprisingly quiet. It uses a swirl chamber design and even has an external fuel cooler — unusual, but that’s how they built it.

However, it only has one fuel-water separator, which doesn’t match China’s real-world conditions (fuel quality, operator habits, outdoor storage, refueling methods). Most Chinese mini excavators have two filters and two separators. As a result, before 3000 hours, failure to drain water caused the fuel pump to run dry, leading to speed drops, overheating, black smoke, and poor power. The engine needed over 2000 RPM to work properly.

I first replaced four injectors — no effect. Eventually, a specialist from Shanghai confirmed it was the fuel pump. Replacing it cost 4300 RMB. Even now, in ambient temperatures around 25°C, coolant temperature easily hits 99°C and there’s still slight black smoke.

Fuel consumption:

About 4.7 liters/hour at ~1900 RPM during normal earthwork.

Hydraulics:

The pumps and valves have worked fine, except for minor oil seepage. The dealer said high temperatures were to blame.

The arm cylinder started to leak due to aging — a new seal fixed it. The bucket cylinder was scratched by improper use — I polished it and replaced the seal, problem solved. Now I don’t let apprentices operate it; careless use can cause expensive wear and tear.

Pilot control:

I replaced the pilot lever oil seals once.

Structures:

Due to using a breaker, working in hilly terrain, and some operator mistakes, the arm cracked before 3000 hours. The dealer replaced it under warranty. Generally, the KX161’s arm looks thinner compared to, say, Komatsu PC60 — which has beefier arms.

Undercarriage:

The standard 550 mm tracks are quite robust and very practical in my region — great for paddy fields and hills alike.

Track rollers:

Before 700 hours, the carrier roller sagged. The dealer delayed replacement until nearly 2000 hours. Later I replaced another one myself, but the problem came back. I finally modified it with dual-end supports — problem solved.

Cab:

Overall, the cab feels cramped and poorly sealed. The layout is rough and makes operators tired easily. For comparison, while the KX161 outperforms the Doosan DH55 in digging power, speed, and traction, the DH55’s cab is far more comfortable, with nice audio and better ergonomics.

Parts:

Parts are expensive! A tiny glass clip once cost over 500 RMB — outrageous. Who would pay that much for a part worth mere cents? I wish the front lower glass had a metal frame — rough operators often step on it, and I end up constantly hauling glass to the site.

Maintenance:

The grease gun holder design is poor. To get the grease gun, you have to open the rear hood and side cover — very inconvenient, and few operators will bother.

Overall:

Generally, the machine runs well with no major breakdowns and rarely delays work. Operation is smooth, speed is decent, and digging power is moderate — not as forceful as the Yuchai YC60-6, Komatsu PC60-7, or Liugong 906C. But at the end of the day, different people have different preferences.

Most importantly, besides the machine itself, management is key: higher hourly rates and more working hours are what really bring in the profit.